Q&A - How Schilling Supply is Responding to COVID-19 Disruption

We sat down with Schilling Supply Company to find out how they are tackling the disruption of COVID-19 and how their day-to-day operations are impacted,

Julian Dawkins

Episerver: In a general sense, how has the Coronavirus outbreak impacted your day-to-day operations?

Amber Kaiser: Many of our suppliers who manufacture sanitizers, masks, gloves and other personal protective equipment have instituted supply pacing programs, which impacts us and our customers. There is a very high demand for these kinds of products right now, so we’re seeing a fluctuation in the industry.

Marc Gloede: To Amber’s point, we’ve certainly seen fluctuation. We’ve been hosting several purchasing meetings. We’re reacting and trying to come up with new sources for these products. But we’re finding the same thing everywhere. Manufacturers have put their inventory on allocation and are protecting their current business first, which we are very respectful of. We’re doing the same thing. Daily, we ensure we’re allocating our inventory first and foremost to current customers. We are making sure we aren’t just serving brand new customers that found our products online and decided to order 300 cases of hand sanitizer because they can’t find it elsewhere. Though we’re doing the best we can to serve new customers during this time as well. So over the past week, Coronavirus impacts have been at the forefront of everything we’re doing at Schilling.

AK: I’ll just add that at Schilling, we’re a generational, family-owned company. We have long-term relationships with many of our customers. It’s been really great to see the industry evolve and watch Schilling evolve along with it. I’m proud that we’ve found ways to serve our customers through new channels like ecommerce. We’re still able to continue serving our customers in traditional ways, but now they have even more opportunities to interact with us. We’re enabled through our digital channels to continue serving our customers even in times like these. As we try to make the best of the evolving situation, we’re prioritizing deliveries for long-term customers and of course healthcare professionals. We’re certainly trying to do whatever we can for everybody else too. This is impacting everyone and we have to put our best foot forward.

Episerver: It sounds like the team at Schilling is doing everything in your power to bend over backward and serve your customers. As a result of you re-allocating time and resources to these areas of your business, are you seeing impacts on other aspects of your business as well? How has it impacted the supply chain or logistics?

MG: The biggest thing that is impacted right now is planning for projects. We’re always trying to make improvements and often it doesn’t feel like there are enough hours in the day. So when something like the Coronavirus drives us to allocate resources and time, we have to neglect some of those other projects. Logistically we’ve been doing okay. But it’s definitely impacted our route efficiencies because we’ve had an influx of orders. In fact, this week we saw our most web orders ever recorded in one day. People are finding our products online and ordering them. It is throwing our routing in the afternoons into a bit of a tailspin. We have to determine whether we are going to be able to fulfill, route and deliver the influx of orders. It does create a bit of panic and urgency.

Episerver: Are existing customers the ones placing the orders or are we talking new business here?

AK: All of the above. It’s definitely a mix of our current customers and new customers. At Schilling we wear multiple hats already, but to see everyone come together during this time and collaborate to best serve our customers speaks volumes about the strength of our team. That’s engrained in our mission anyway, but to see it pulled together under this kind of pressure is really neat. The care we have for our customers makes me proud to work here. We’re communicating promptly and effectively with our customers. We’re providing guidance and referring customers to the CDC. And, of course, we’re making sure our own team stays healthy so we can continue to best serve our customers.

Episerver: It’s clear you are doing what you can to serve your customers well. You mentioned you’ve gotten more web orders. Are you also seeing increased phone or fax orders? If so, how are you keEpiserverng communications going when you may have to deliver news that you can’t fulfill certain orders?

MG: Our customer service team has been doing an excellent job. While orders are being placed, they are communicating potential ordering challenges. They’re letting our customers know upfront that we have certain limitations. For the most part, our customers have been really understanding. When we do short shift product, our customer team reaches out to all the customers and lets them know what was shorted on their shipment, why it was shorted, when it will be delivered and so forth. We don’t have all the answers and we can’t prepare for everything, but we are certainly trying.

Episerver: How has this impacted your relationship with your suppliers?

MG: Many of our suppliers are doing a fantastic job. Some of them will provide a weekly report that outlines what we are allocated, which is really helpful. We understand that many of our suppliers have to protect their current business. The only thing that holds times like these together is mutual trust. When H1N1 hit, we saw the same kind of impacts to business. We saw mass panic, many distributors were looking for ways to source new items and there were many supply shortages. We are doing our best to do what’s right for our customers and we expect our suppliers to do the same thing on their side. We are all in this together.

Episerver: Great, so let’s shift gears a bit to talk about digital. How has ecommerce for example, helped you during this time?

AK: People continue to find our products through our website. In general, customers really like our site. They can get all their products in one place and order online. The website helps us communicate and provide the information our customers are looking for. But more importantly, we’re blessed with a really great team that’s doing everything they can for our customers during this time.

Episerver: So you’ve seen a spike in sanitation products, masks, wipes and other personal protective equipment. Any move in demand for other products?

MG: I don’t mean to call it panic buying, but there’s a bit of that going on right now. Everyone is fearful that the supply chain may be impacted by COVID-19, so it seems like everyone is ordering more of everything. But it seems that there is a specific demand for products that are sanitation related like towels, tissue, wipes and chemicals. Those products are skyrocketing. But it does seem like there’s an overall trend up for nearly all our products. People are stocking up.

AK: It will be interesting to watch how ordering changes as the media coverage slows down and panic levels decrease.

Episerver: Speaking of, how are you planning for your inventory control? This could slow down in a couple weeks, or it could slow down in October. Are you able to plan for that?

MG: Unfortunately there’s not a lot of planning we can do. But I think what’s pretty common is that we’re communicating that we won’t be able to take returns on anything beyond normal usage patterns. For those customers that seem to be putting in a year’s worth of supply of hand sanitizer, we won’t be able to accept returns on those for the same reasons they want to get rid of it. But for the most part, we’re trying to be reactionary and get duplicate sources on some of these products. But if it stops two weeks from now, we’ll need to deal a bit with that backlash. We saw a lot of this back when H1N1 hit. After that died down, we were left with large amounts of hand sanitizer, masks and other related products. Eventually we had to sell those products at a discounted rate. But when something like this happens, you have to react to the market quickly and get customers what they need. I think everyone is trying to protect the backlash of product coming back after these large orders come through. Our manufacturers have communicated this message to us as well, that anything beyond normal usage patterns won’t be able to be accepted as returns. They’ve ramped up production and they can’t afford to accept returns.

Episerver: We recently heard a story about a manufacturer here in the U.S. who bought a bunch of extra equipment and ramped up production during the MERS epidemic and then literally overnight orders stopped. And it almost bankrupted his entire company. So that must be a real concern for not just distributors like Schilling, but also for manufacturers. Is that pretty accurate?

MG: Yeah, absolutely. They have to protect their businesses for the future. It’s easy to jump when the demand is there. But if next week this pandemic goes away, you might be left with a ton of extra inventory. You’d be left holding your wallet with a lot of added expense. You have to do what you can to serve your customers, but, at the same time, you can’t just shift your entire business.

Episerver: So you’ve been really proactive with updating the website, communicating with your customers, fielding calls and making adjustments to your routes. Have there been other areas of the business that have changed because of this? Any expanded will-call office hours or anything like that?

MG: We haven’t seen the need for those kind of adjustments just yet. We have seen a larger amount of will calls. We’ve seen average individuals come in and order our products. But we haven’t seen the need to require longer hours or add staff just yet. However, we recognize that could change at any moment. We’re hearing retailers are out of hand soap and sanitizers. We’re even seeing items like toilet paper running low. So if that continues, it may require some changes.

Episerver: No kidding. Curious though, why toilet paper? Understand the need for people to go buy sanitizer and soaps, but why do you think toilet paper aisles in stores like Costco, Walmart and Target are sitting empty?

AK: Messaging from the media certainly has people on alert. With talk of quarantines, I think people just want to be prepared. I know there’s a shift in purchases of bottled water right now too, probably for the same reasons. So if there’s talk of getting quarantined for an extended amount of time, people are stocking up their households with the essentials as a precaution. A sense of action can be comforting in situations like this.

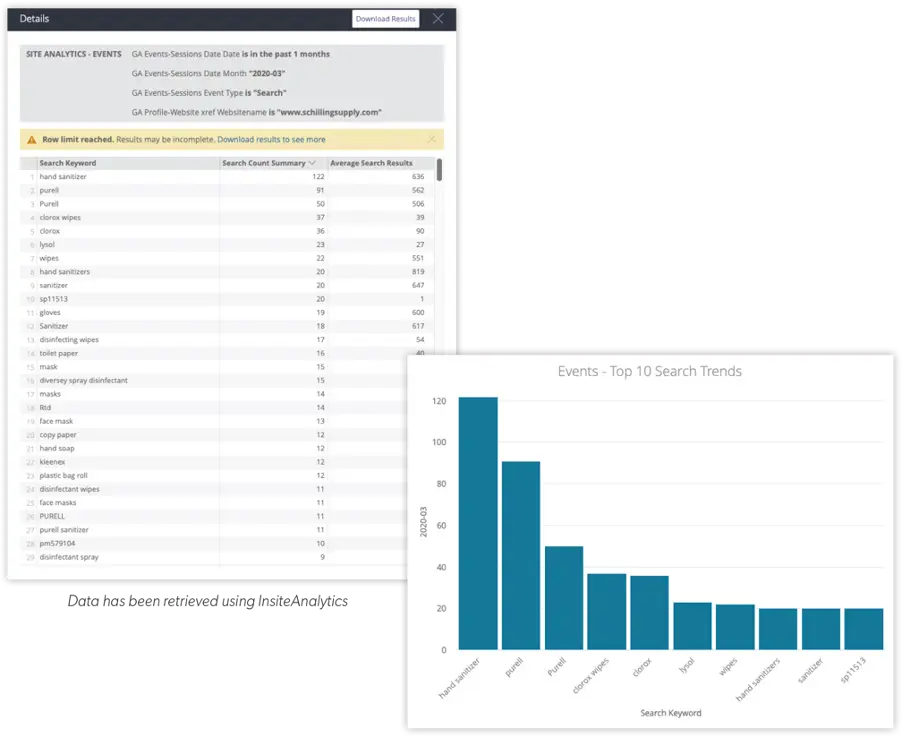

Episerver: Right. Yeah, actually we were looking at the search events on your website over the last quarter. It was interesting to see the most recent searches were all things like hand sanitizer, Purell, Clorox wipes, Lysol and other things of that nature.

MG: Yeah definitely. If we could go back six months and stock up on hand sanitizer by the truckload, that would be fantastic for business! Unfortunately that’s not the case.

Episerver: So, when you have to make changes to the business due to impacts from the Coronavirus, who makes the calls? Talk to us about the people leading the charge against these disruptions.

MG: It depends on the level of change. If it’s a major change, that will involve investments upfront and any potential impact to our customers, the President is definitely going to be involved in those discussions. If it’s operational changes with truck routes, our distribution manager would be involved as well as our customer service supervisor. Changes to our website would be handled by someone like Amber and myself. Procurement has seen a bit of a shift just due to the overall panic this outbreak is creating. I have connected with the procurement manager and the purchasing team to discuss alternative products, new suppliers and shortage. It really depends on the area, but it’s typically a team discussion. At the end of the day, we’re all in this together.

Episerver: If you were giving advice to another company like you to prepare for the Coronavirus, a natural disaster or some other disruptive force, what would you say? How do businesses prepare for the unexpected?

AK: I’m going to mention something that isn’t even specific to Coronavirus but has to do with just maintaining a foundational business. Empathy. We do our best at Schilling to show empathy for our customers and work to understand them. When you have that sort of a relationship, you’re going to understand what their needs are and be able to serve them even when there are challenges. At Schilling we’re very interactive with our customers. In relation to the website, just like you brought up our recent search terms, you can also see a lot of insight through analytics by looking at click behavior and things like that. It gives you several different lenses to understand and empathize with where the customers are coming from, what their needs are and how we can best help them.

MG: I’d add that you can’t always be fully prepared for these types of situations. If you follow it closely and you think something like this is going to happen, you can try to get ahead and react by stocking up on products. But if that doesn’t play out, then you are stuck holding all of that investment. I don’t think many distributors would take it upon themselves to try to read and predict the market to that extent. But if you’re just upfront with your customers about the reality of the situation, you’ll be in good shape. Share manufacturer communications, let them know what’s happening, share helpful resources when something frightening is circulating all over the media. There’s a lot of steps you can take to respond. There has been next to no backlash from our customers. Empathize with what they’re after. Try to offer alternative products if you can. We’re searching hourly for anything we can try to get our hands on. Overall, the biggest thing is just communication. Be upfront with your customers. Protect the customers who have been loyal to you for years.

Schilling Supply is just one of many wholesale distributors seeing impacts from the Coronavirus outbreak. The outbreak is disrupting supply chains everywhere. The effects are seen far and wide across many industries. In the midst of turmoil and panic, we are all in this together. At Episerver, we have transitioned to remote work and canceled non-critical travel. We are grateful to our customers and partners whose support and agility make this possible. The team at Episerver is working hard and taking precautionary steps to keep our customers’ businesses moving. We do not foresee any impact of the COVID-19 outbreak in our ability to serve and support customers, partners and organizations. Still we are planning for the unexpected. All of us are part of the solution. Learn more about Episerver’s COVID-19 Plan, Processes and Policies.